HK Design ProIn the communication with different customers, the questions are summarized and answered, so that you can understand and solve the problems you are concerned about in advance when designing products for subsequent work.

HK Design ProIn the communication with different customers, the questions are summarized and answered, so that you can understand and solve the problems you are concerned about in advance when designing products for subsequent work.

1. Common design issues

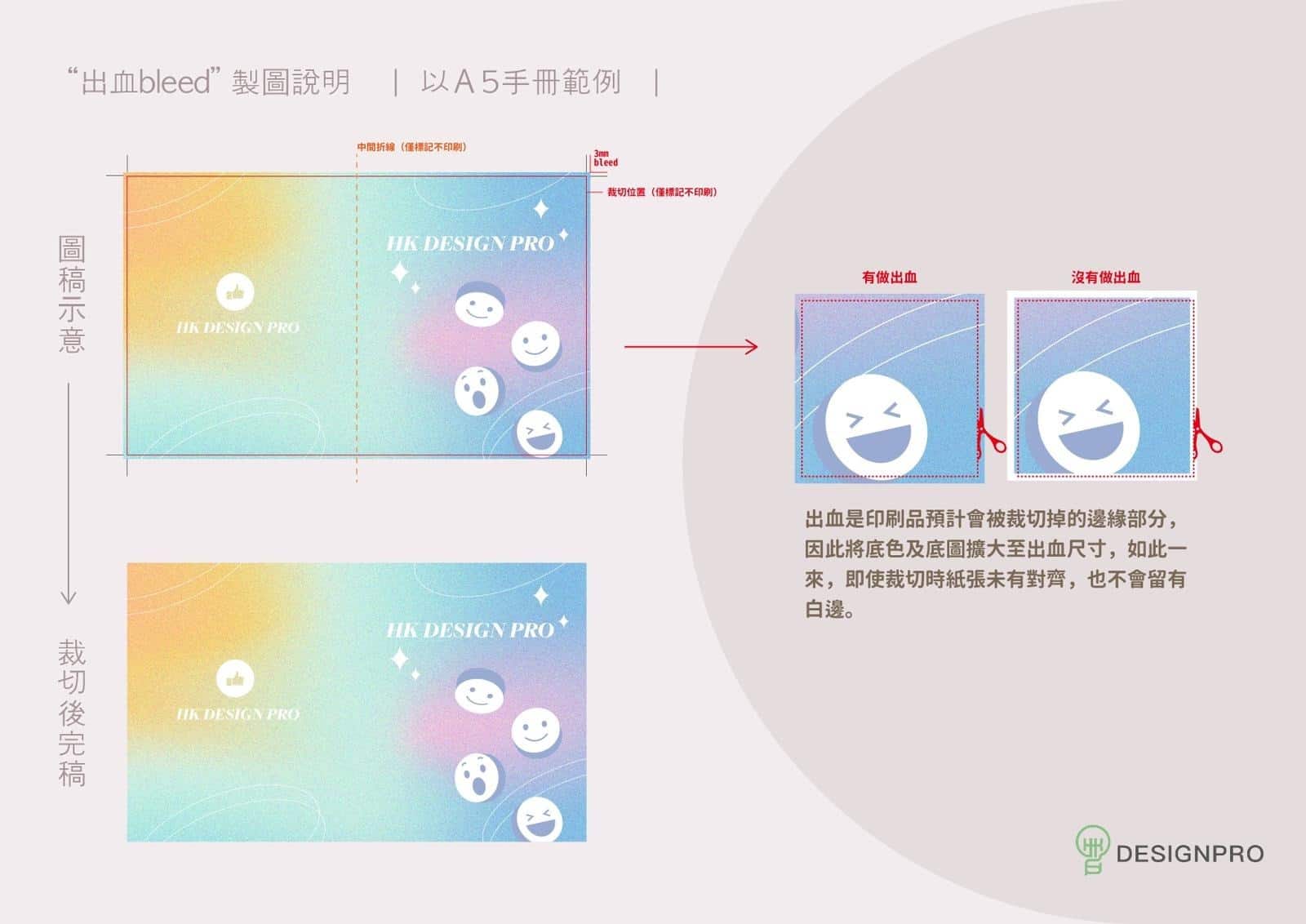

Q1. What is a bleeding line and how to make a bleeding line?

A:bleeding lineis a printing term that refers to trimming before printing beyond the edge of the paper. This is done to allow for small variations in the cutting process, which without appropriate modifications may result in prints with uneven borders. If you want to create a bleed line, you need to extend the element you want to print to at least 0.125 inches (3 mm) (the bleed) from the edge of the page. For example, if you have a 3.5-inch by 2-inch business card and you want the image to extend to the edges of the card, you will need to create a 3.75-inch by 2.25-inch document. This will give you 0.125 inches of bleed on each side of the card. When setting up a document in a design program such as Adobe InDesign or Illustrator, you need to make sure the document size is set to include bleed lines. You can go to the "Document" menu, select "Document Settings", and then enter the dimensions of the document, including bleed lines. Once your document is set up with appropriate bleeds, you can design the document as normal. Just be sure to keep any important text or graphics at least 0.125 inches away from the edge of the page to ensure they don't get cut off during the trimming process.

Q2. What does glossy paper look like?

A:glossy paperHas a reflective surface that gives printed images a vibrant and saturated look. The surface of the paper is coated with a smooth surface, which gives it a glossy appearance. This finish can make colors look more vibrant and contrasting, and it can also make the paper feel smoother. One of the main benefits of using glossy paper is that it produces very sharp and detailed prints. The glossy surface of the paper helps reflect light, making printed images appear sharper and clearer. This makes it a good choice for printing high-resolution photos or other detailed graphics. However, be aware that glossy paper is prone to fingerprints and smudges, and glossy surfaces make it difficult to read text from certain angles. It's also more prone to glare in bright lighting conditions, which can make it difficult to view printed images. Overall, glossy paper is a good choice for printing high-quality images and graphics that require vibrancy and detail. It is commonly used for printing marketing materials such as brochures and business cards, as well as printing photographs and artwork.

Q3. What does matte pink paper look like?

Matte paperFeatures a non-reflective finish that makes printed images appear more subtle and low-key. The surface of the paper is not coated with a smooth finish, so it has a softer appearance. This can make the colors appear less vibrant and contrasting, and can also make the paper feel slightly rougher. One of the main benefits of using matte paper is that it reduces glare and reflections. The paper's non-reflective finish means it's less prone to glare in bright lighting conditions, which makes it easier to view printed images. This makes it a good choice for printing documents that need to be easy to read, such as reports or manuals. Matt paper is also more resistant to fingerprints and smudges than glossy paper. The paper's non-reflective finish means it's less likely to pick up oil and dirt from your hands, which helps keep printed images looking clean and fresh. Overall, matte pink paper is a good choice for printing documents that need to be easy to read and process. It is commonly used for printing marketing materials such as brochures and business cards, as well as printed documents that will be used in professional or educational settings.Q4. What is UV printing?

UV printingIt is a printing process that uses ultraviolet (UV) light to cure (dry and harden) ink. This is done by applying ink to the substrate (the material being printed on) and then exposing it to UV light, which causes the ink to harden almost instantly. One of the main benefits of UV printing is that it produces very high-quality prints, with vibrant colors and sharp details. The UV curing process allows the ink to bond directly to the substrate, resulting in long-lasting prints that are resistant to smudges and fading. UV printing is commonly used to print on a variety of materials, including plastics, metals and glass. Another benefit of UV printing is that it is a relatively environmentally friendly printing process. UV ink does not contain volatile organic compounds (VOCs), which are harmful to the environment and cause air pollution. Additionally, UV printing produces very little waste because the ink cures almost instantly and does not require the use of solvents or other chemicals to dry. Overall, UV printing is a high-quality printing process suitable for a wide range of applications. It is commonly used for printing marketing materials, such as brochures and business cards, and for printing on a variety of substrates, including plastic, metal and glass.

Q5. What is a matte film?

Matt powder coatingIs a process where a thin plastic film is applied to a printed product to protect it and give it a matte pink effect. This film is applied through heat and pressure, and it bonds to the surface of the printed material to create a smooth and durable surface. One of the main benefits of matte powder lamination is that it protects printed materials from wear and tear, such as fingerprints, scuffs and fading. Laminated film creates a barrier that helps maintain the quality of the printed image over time. Matte powder lamination is also a popular choice because it gives printed materials a professional and high-quality appearance. The matte finish of the laminate is non-reflective, making printed images easier to read and view in a variety of lighting conditions. Matt powder lamination is commonly used for printing marketing materials such as brochures and business cards, as well as printing books and other documents that require durability and longevity. It is also a popular choice for products that require frequent handling, such as menus and point-of-sale materials.Q6. What is optical film?

Light filmIt is the process of applying a thin layer of plastic film to the printed matter to protect it and make it glossy. This film is applied using heat and pressure, and it bonds to the surface of the printed material to create a smooth and shiny surface. One of the main benefits of optical film is that it protects printed materials from wear and tear, such as fingerprints, scuffs and fading. Laminated film creates a barrier that helps maintain the quality of the printed image over time. Gloss film is also a popular choice because it gives printed materials a professional and high-quality appearance. The glossy side of the laminated film is reflective, making printed images appear more vibrant and colorful. Gloss lamination is often used for printed marketing materials such as brochures and business cards, as well as printed products that will be displayed in retail environments. It is also a popular choice for printed products that need to be bold and eye-catching, such as posters and display graphics.Q7. What is glue binding?

Perfect BindingRefers to the process of binding books or other printed materials with glue. This process is also known as perfect binding. In the perfect binding process, the edges of the spine of printed pages are coated with glue and then pressed against a backing material, such as paper or cardboard. The pages are then clamped together until the glue dries, forming a strong, durable bond. Perfect binding is a popular choice for binding books, magazines, and other printed materials with moderate page counts (usually between 40 and 400 pages). This is a relatively inexpensive binding method that allows the book to lie flat when opened, making it easier to read. However, perfect binding may not be as durable as other binding methods, such as case binding (also called hardcover binding) or saddle binding. It is less suitable for use with heavy-use binding materials, as the glue will break down over time and the pages will loosen.

Q8.What is thread-locking glue binding?

Thread BindingRefers to a specific type of book binding process that uses plastic spiral binding elements, also called "coils," to hold the pages together. This process is also called spiral binding or coil binding. In the perfect binding process, a plastic coil is inserted into a hole punched along the ridge edge of the printed page. The ends of the coil are then crimped or "locked" together, holding the page securely in place. Seam binding is a popular choice for binding materials that need to lay flat when opened, such as notebooks, calendars and manuals. It's also a good choice for materials that will be used heavily, as plastic coils are more durable than other binding methods, such as perfect binding (perfect binding) or saddle stitching. However, perfect binding can be more expensive than other binding methods, and it may not be as aesthetically pleasing as other options, such as hardcover binding (also known as hardcover binding). It is also not suitable for binding material with a large number of pages, as the thickness of the plastic roll may make the book too bulky and uncomfortable to hold.

Q9. What is hardcover?

A:hardcoverRefers to the process of binding a book or other printed material in a hardcover. This process is also called case binding. In the hardcover process, the printed pages are gathered and sewn together and then glued to the spine edges of the hardcover book. The cover is then attached to the spine using various techniques such as glue or sewing. The final product is a hard cover book, securely bound to the pages. Hardcover is a popular choice for binding high-quality books such as novels, textbooks, and reference materials. This is a durable binding method that can withstand heavy use and also gives the book a professional and high-quality appearance. However, hardcover may be more expensive than other binding methods, such as perfect binding (perfect binding) or saddle stitching. It's also not ideal for materials that need to lay flat when opened, such as notebooks or calendars, as the hardcover can make it difficult to fully open the book.

Frequently Asked Questions

You can browse byHK Design Pro official websiteGet more relevant knowledge.

you canHK Design ProContact the staff on the official website and they will answer your question after they know it.

It can help you initially screen out some unnecessary options when choosing printing products, allowing you to make better choices.

Related posts:

Is graphic design time consuming? Five best design platforms/websites to help complete the design | Hong Kong Freelance Designer

Comparison of the advantages and disadvantages of electronic drawing and hand-drawn illustration design methods | In-depth understanding of different drawing styles and differences

[7 types of drawing] Electric drawing service|Comic drawing hand-painted price comparison!