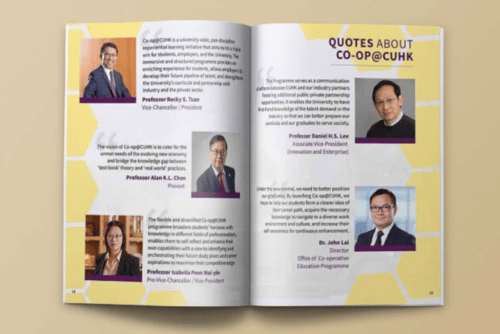

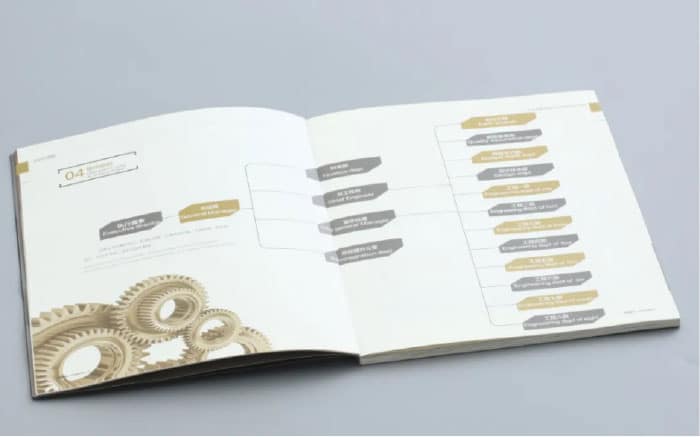

In recent years, the forms and patterns of hardcover book printing and processing have emerged one after another, and the processing technology has been continuously renovated. Many companies make great efforts to present unique brochures to customers and create a good corporate image. In addition to the common drumming and bronzing processes in book printing, there are many uncommon processes. Today we briefly talk about some special processing techniques for albums that have been popular in recent years.

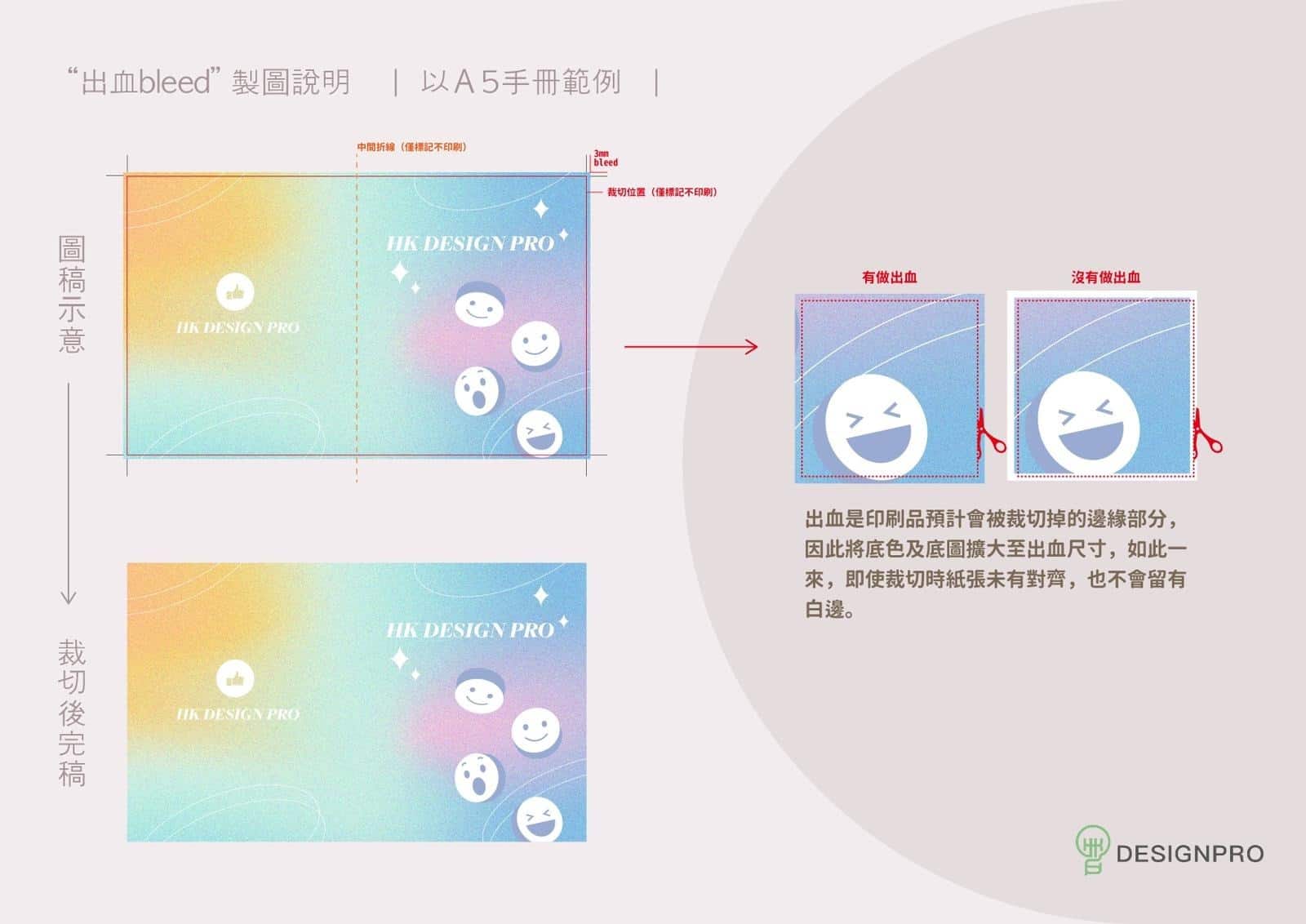

one. Hardcover book printing processing indentation:

1. Process purpose: If the paper is too thick or the pulp is too brittle, if the printed product is directly folded, the inner pulp will be exposed, resulting in serious damage to the booklet. Indentation is a good way to solve this problem.

Production Method

It is to use a crimping knife or a crimping die to press out line marks on the sheet material by pressure, or use a rolling wheel to roll out the line marks on the sheet material, so that the sheet material can be bent and formed at a predetermined position. Usually indentation is divided into three principles: flat pressing, rolling pressing, and rotary pressing, which have different advantages and disadvantages and suitable occasions.

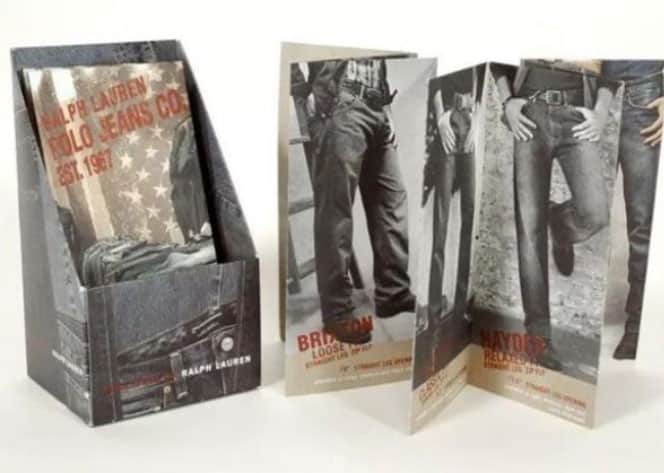

two. Closing line: also known as dotted line, dashed line, needle thread, dental floss, etc.

Sometimes printed materials, such as tickets, cards, postcards, and outbound receipts, can be easily torn as needed, and a round hole line needs to be punched at the torn position, which is also a commonly used post-printing process. This kind of craftsmanship is common in the catalogs of some sales companies.

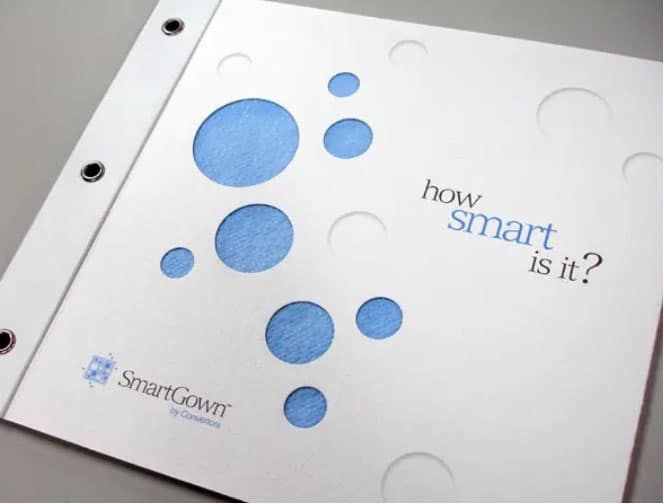

three. Punch:

Punch a hole in the print according to the required size to enhance the aesthetics and sense of design.

The punching process is widely used in the album design of many companies.

Four. Die-cutting: The die-cutting process is the most commonly used process after printing.

![[Books] Hardcover printing and processing 4 asdfasv](https://hkdesignpro.com/wp-content/uploads/asdfasv.jpg)

Process purpose: Cut out the desired irregular and arbitrary shapes with a die-cutting knife to make the album print more creative.

Production Method

The die-cutting knife is used to form a die-cutting plate according to the pattern required by the product design.

five. Label

By adding label elements to the edge of the album, the function of the album is visualized, the design sense of the album is improved, and the content of the album is clearly presented.

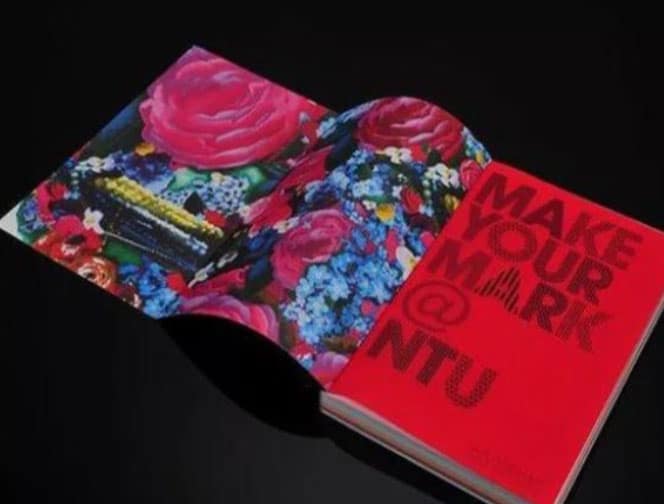

six. Inside pages can be revealed:

Folding and extending the inner pages of the picture album, it can be opened when flipping through, and is often used in the promotion of picture albums in museums, libraries, etc.

seven. Glazing:

Craft purpose: to enhance the texture of books and periodicals and make them look more beautiful.

Production Method

Glazing is to coat or spray the surface of the printed matter with a layer of colorless and transparent paint. Leveled. After drying and calendering, a thin and uniform transparent and bright layer is formed on the surface of the printed matter. There are three forms of glazing, namely coating, calendering and UV glazing, which can enhance the moisture resistance, sun protection, abrasion resistance, antifouling, etc. of the printed matter. Water resistance.

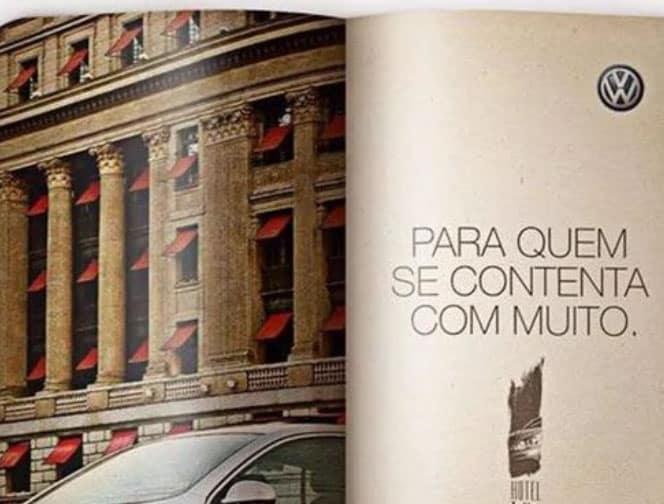

Eight. folding:

Enhance the sense of design, easy for customers to watch, and reflect their own ideas

Folding is a common post-press process, including half, three, four, five, accordion and other folding methods. Common in the production of some creative albums.

Nine. Kim Cong:

It is to sprinkle gold powder on the paper with glue, showing a dazzling visual effect, which is mostly used in the production of books and periodicals for companies such as weddings.

ten. Flocking:

Brush a layer of glue on the surface of the print, then stick somefluff material, so that the surface of the printed matter has the effect of flannel. It is often used in the production of company books and periodicals such as home improvement and beauty.

eleven. Embossing:

Purpose of the process: Also known as imprinting, pressure is used to press graphics or text on the surface of printed matter to achieve special tactile and visual effects.

Production Method:

It is to use a concave-convex mold to produce plastic deformation of the printed matter under a certain pressure, so as to perform artistic processing on the surface of the printed matter. The surface of the embossed printed matter presents patterns and textures of different shades, with obvious three-dimensional relief, which enhances the artistic appeal of the printed matter.

Need high-quality design printing?

![[Books] Hardcover printing and processing 12 DesignPro Logo](https://hkdesignpro.com/wp-content/uploads/DesignPro-Logo.png)

If you would like to discuss your design printing needs with us, please contact us at [email protected].

Telephone:+852 67552667

e-mail:[email protected]

URL:https://hkdesignpro.com

![[Books] Hardcover printing and processing 14 年報設計案例 |6種年報風格推薦](https://hkdesignpro.com/wp-content/uploads/2-11.jpg)

![[Books] Hardcover printing and processing 15 小冊子 設計大揭密|5種設計技巧讓你脫穎而出!](https://hkdesignpro.com/wp-content/uploads/young-female-designer-working-project-500x333.jpg)